The friction materials used by ICER Brakes in the manufacture of brake pads for industrial vehicles and lorries are made up of the most advanced raw materials, fibres, and lubricants, reinforced with the use of 2 pre-mixtures to create a dual matrix, which:

- Ensures optimum results in terms of performance, noise, and safety.

- Considerably reduces maintenance costs of the vehicle

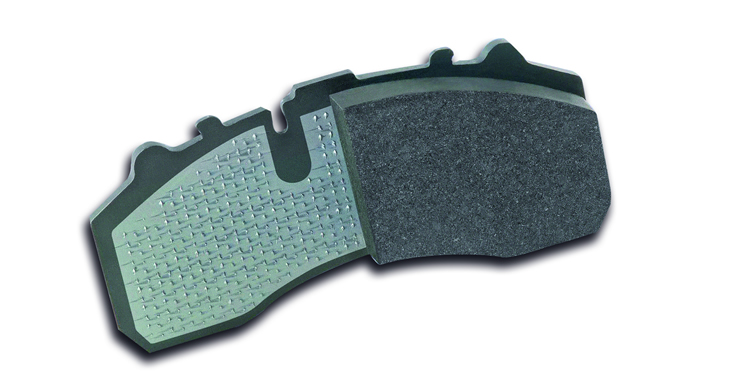

In addition to this, the mechanical retention system provides the following advantages:

Increases shear resistance to more than 450 Newton / cm², with 100% adherence of the friction material to the metal support, exceeding the values demanded in today’s market.

Increases shear resistance to more than 450 Newton / cm², with 100% adherence of the friction material to the metal support, exceeding the values demanded in today’s market.

- Improves thermal conductivity by more than 18%, dissipating (through the support) more of the heat generated on the friction surface. Extends the life of the brake pads and discs, reducing the appearance of cracks and microfissures.

- Increases the contact area between the friction material and the metal support by between 2 and 2.5 times, because the effect is three dimensional.

By implementing the strictest quality control systems, ICER’s brake discs give customers better performance in all weather conditions. Whether on the “Rossfeld” alpine descent or on a slippery motorway, ICER’s brake pads guarantee safety.